FUJI OOZX’s R&D activities

Our research and development efforts center around four fields: Research, Design, Equipment Engineering, and Production Engineering Development . Our Research section is responsible for product development on a contract basis, up-front development of new products, and the functional evaluation of the products we develop. The Design section serves as our point of contact with customers, to explore the development of product applications and cultivate new demand for our products. The Equipment Engineering section is responsible for the development of specific production equipment, and the Production Engineering Development section is engaged in the improvement of our manufacturing processes and the development of new production methods. The activities of these four sections are coordinated to create the best possible solution for each of a wide range of issues, including quality improvement and cost reduction.

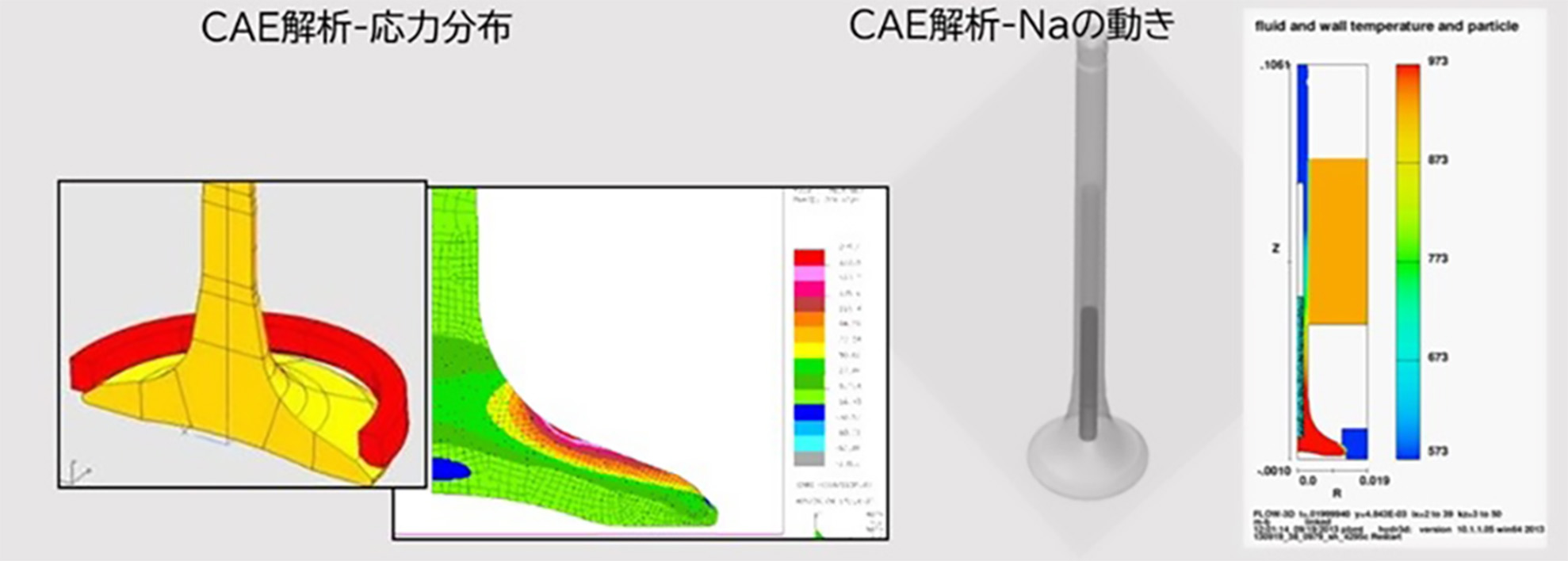

Product development

FUJI OOZX is engaged in the development and production of engine valves for motorcycles and ships, as well as automobiles. Since we are involved with such a wide variety of transportation types, we are able to apply what we have learned from working in one area to enhance our development capabilities in the other areas as well. This makes it possible for us to tackle even the most difficult development projects. Our track record shows that our development capabilities are greatly appreciated, and our customers see us as an extremely competent partner company. In the automotive industry, recognition of our reliability has now grown to the point that the majority of Japanese automobile manufacturers are taking delivery of our engine valves.

The manufacturing system

Our manufacturing site is intended to turn out high-quality products as efficiently and safely as possible. Therefore, we put efforts every day into creating more productive and safer working conditions. Proposals obtained through these improvement efforts are submitted to the Production Engineering Development section.

Inspection (testing)

A new test center, equipped with the latest technology, was completed in the summer of 2016 for the evaluation of product functions such as combustion analysis, temperature measurement, and durability testing. This center makes it possible for us to perform more precise testing than ever before. We utilize data obtained at this center to expand our sales activities based on product proposals, and at the same time this information contributes greatly to our European and U.S. automaker sales drives. In addition, the new test center also helps improve the reliability of products manufactured by our overseas subsidiaries. It has led to strengthening our overall development capabilities even more.