Hollow valves (Hollow-stem and hollow-head valves)

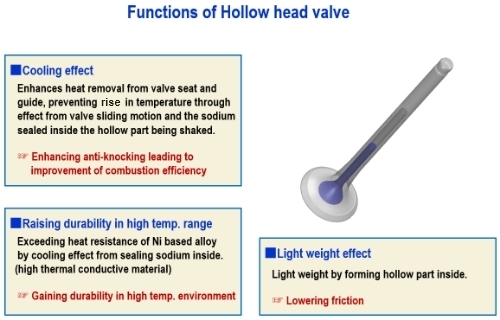

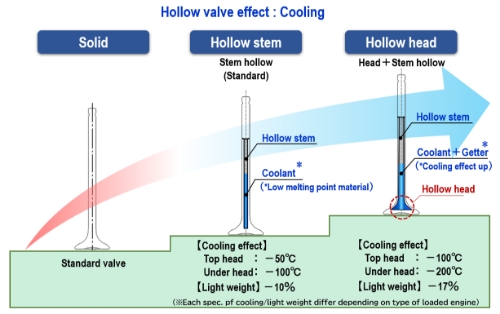

Hollow valves have a cavity inside that is filled with sodium to serve as a coolant. This cooling action lowers the temperature of the valve itself, enabling it to withstand use at higher temperatures.

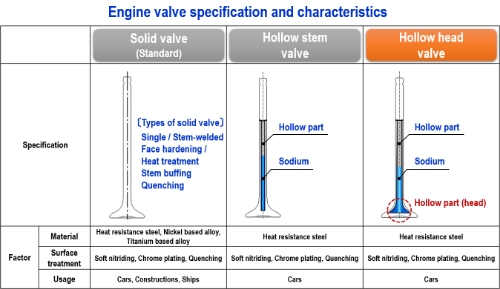

We offer three types of hollow valves to meet a wide range of market needs: hollow-stem valves, super-hollow-stem valves, and hollow-head valves. In this last type, the hollow space runs through both the valve stem and the head.

The FUJI OOZX hollow-head valve

Our original technical know-how makes it possible for us to produce these high-quality hollow-head valves.

FUJI OOZX's hollow-head valve is designed to be super safe. There are no welds in the head portion, which is exposed to very high temperatures during the engine's combustion stroke.

This is achieved through our proprietary forming technology, which uses a cold forging process to create a hollow space in the valve head.

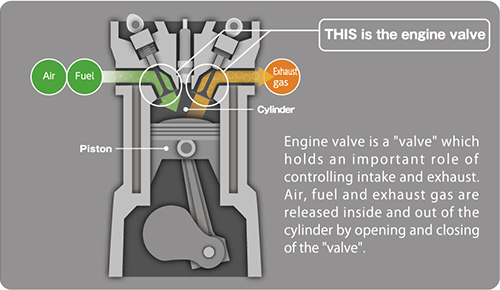

What are the functional demands placed on engine valves?

(1) Engine valves are exposed to very hot gases (over 1000°C within the cylinder) under very high-pressure combustion conditions, so they must be able to resist these stresses reliably.

(2) Engine valves move back and forth at high speed (several thousand times per minute), so they must be light in weight in order to keep mechanical losses to a minimum.

The specific effects of hollow-head engine valves

FUJI OOZX's hollow-head valves are made by the application of a unique cold forging technique that makes both the stem and the head hollow. The continuous hollow helps prevent the temperature of the surface exposed to the combustion chamber from becoming too high, and thereby prevents abnormal combustion (knocking). This, in turn, leads to higher engine performance and better fuel economy, contributing to reducing the engine's impact on the environment.

History of the Hollow-head valve

The origin of hollow-head valve began with the development and manufacture of “Zero” fighter valves using the best technology available at the time.

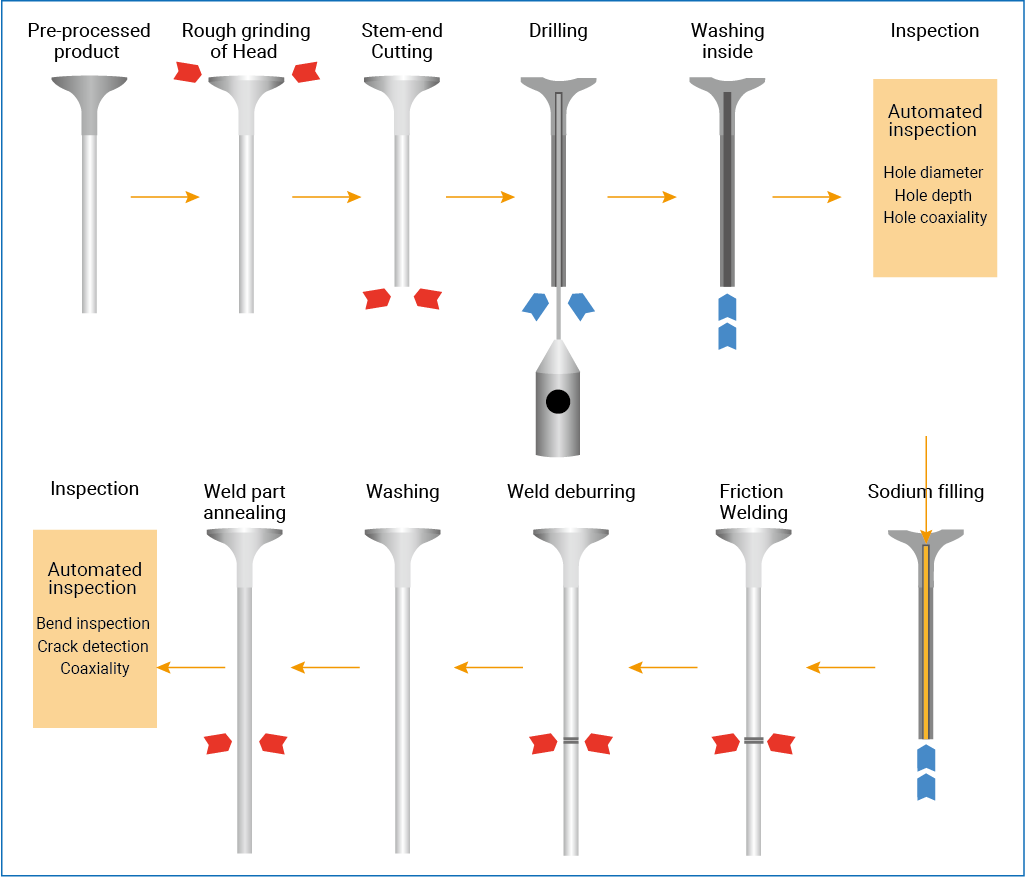

Stem Hollow Valve Manufacturing Process

FUJI OOZX, as one of the largest engine valve producers in the Asian region, spares no effort to produce high-quality products. We develop new materials and equipment, and innovate creative production processes.

We strive for consistent quality control over everything from initial materials to finished products, in our determination to support the advancement of engine performance. We also design production equipment in-house for greater efficiency.

As an industry leader in the production of engine valves, we are also engaged in the development of proprietary technologies for forging and precision grinding heat-resistant steel, which is a difficult-to-machine material. In addition, we take the initiative in the pursuit of appropriate production processes to ensure stable quality.

The combined outputs of our Shizuoka and Fujisawa Plants constitute one of the biggest sources of manufactured engine valves in the Asian region.

These plants are equipped with MUGs (Multi Use Grinders) of our own design and automatic inspection machines to pay eagle-eyed attention to the accuracy of dimensions and shapes, and by using leak testers to inspect all products, we can guarantee that our valves function to the highest standards. We are committed to manufacturing the highest quality engine valves, that meet our customers' exacting needs.