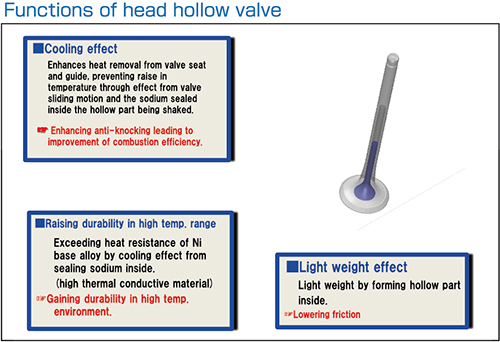

OOZX head hollow valve does not have any welded portion on the head, making its structure highly safe. This is made by the only one technical skill in the world using cold forging, forming into a hollow shape.

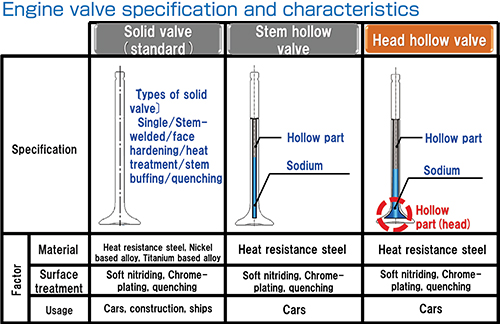

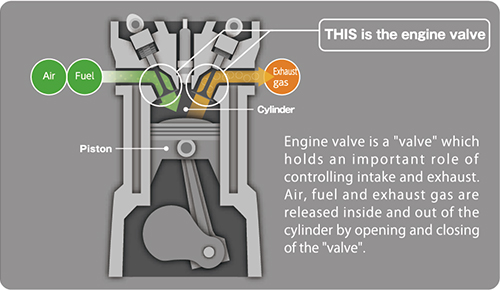

1) Heat resistance is requested for engine valves since the temperature is raised to 1000℃(1832°F) inside the cylinder due to being exposed to hot combustion gas.

2) Light weight is requested for engine valves since the engine valve moves vertically a thousand of times in one minute.

OOZX head hollow valve is processed by original integral hollow processing technique through forging by making the head and stem part of the hollow valve, sealing sodium inside, which holds high thermal conductivity effect.

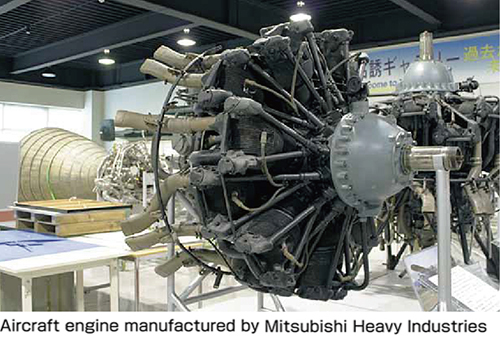

Started by developing and manufacturing engine valves (hollow valves) for aircrafts by using the best technology back then.

FUJI HOLLOW VALVE Inc.

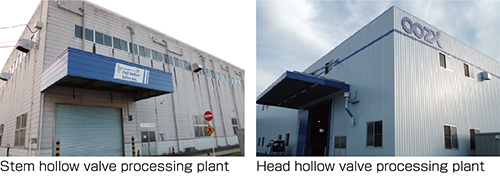

FUJI HOLLOW VALVE Inc.In 2016, FUJI OOZX Inc. and Mitsubishi Heavy Industries Machine Tool Co., Ltd. integrated its business and established a company dedicated for hollow valve processing. In December 2017, a new head hollow valve processing plant was completed and started its operation.